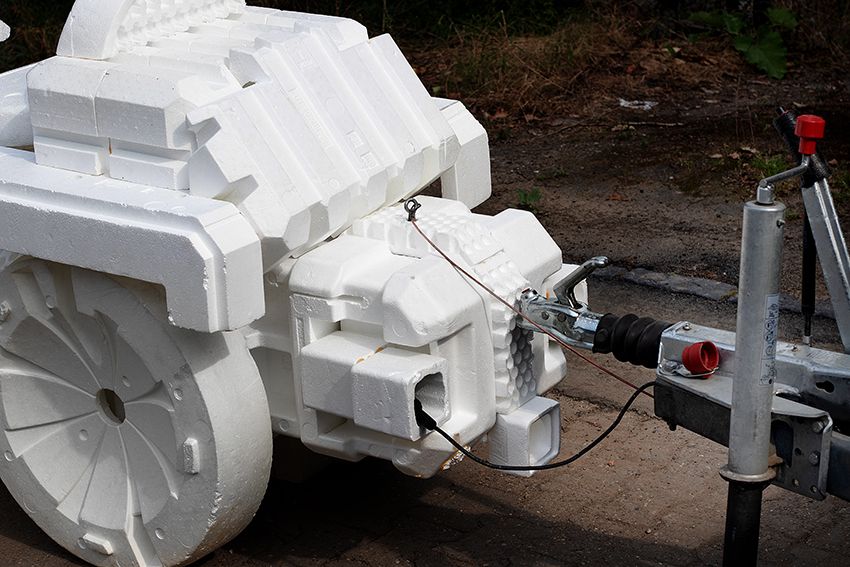

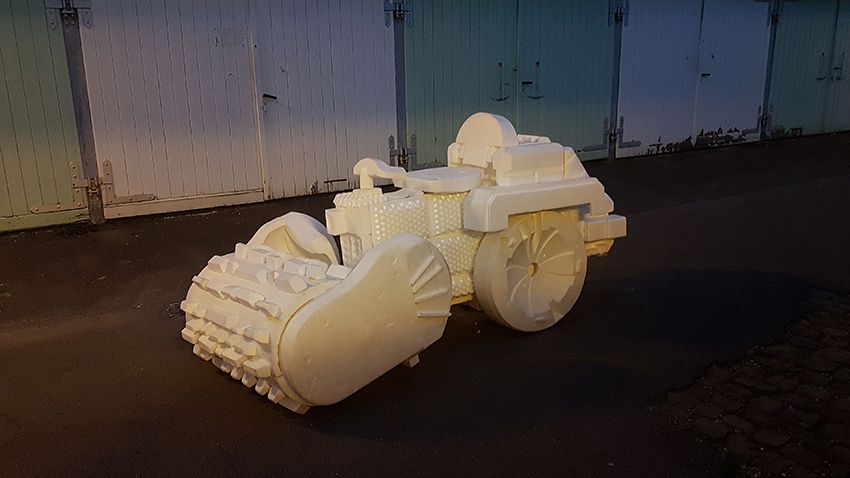

Riding soil compactor roller

Material: Styrofoam packaging

Powerful machinery is fascinating in its own special way. Anyone strolling around building sites has plenty of opportunities to encounter such machinery, become acquainted with it and try to understand how it works. There is the large soil compactor roller, a monster of a machine that weighs several tons and is used in underground mining to press down the ground in excavated construction pits,then its delicate, cable-controlled toy-like version used to prepare football pitches. When faced with the large compactor’s threatening steel drum we humans feel exposed and vulnerable. In order to address this feeling, a hybrid object was constructed tooriginal scale, one that was not dissimilar to a riding mower: a riding soil compactor roller, a roller that could be controlled and managed.

Building dummies of construction machines to scale using Styrofoam packaging presents an exhilarating challenge. Reinterpreting the predetermined geometries of the packaging cases as machine elements is tricky, exciting and full of surprises. A meditative puzzle game in three dimensions. These functionless objects find their raison d’être in simulated work in changing environments. The soil compactor roller belongs in a landscape. It laboriously flattens the ground, overcomes resistances, but also encounters barriers. An encounter with a highspeed train spells destruction, complete atomization, even for the most resistant Styrofoam sculpture. On impact, it disintegrates into tiny pellets –but not into dust. This would only be produced by shredding the material, something reserved for specialized companies.

After being employed on the soil, the roller is serviced, cleaned and parked. It returns to the dummy warehouse until it’s time for the next job.